With the rapid development of society and the explosive improvement of scientific and technological level, many previously seemingly impossible scientific and technological levels have been gradually realized. The most direct is many electronic products with camera function. Then many electronic packaging box have gradually been paid attention to by packaging factories. It is not difficult to find that in recent years, the packaging color Electronics Packaging Box used to load 3C, USB flash disk and earphones have become more and more tasteful, unlike in the past, it was just a pit box.

With the progress of the times, there is an epoch-making progress in the packaging box of electronic products, that is, the Neto. The earliest electronic products were actually limited to mobile phones and cameras. The paper electronic box of these products were basically pit boxes made with a mobile phone brand as the representative in the 1990s. There is no doubt that the Neto is actually a piece of paper, which is stuck in the packaging box of electronic products, Then through the hollowed out technology, the products can be knocked to the advantage and placed in the hollowed out position, while some other accessories are basically packed in plastic bags that can be sealed. Although it looks old-fashioned now, it was a kind of packaging design with considerable specifications at that time.

So what about the inner holder of electronic product packaging box now?

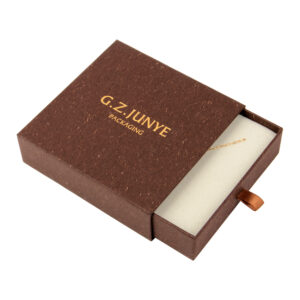

In fact, this is the same as the customized specifications of many gift boxes. Usually, the inner support of electronic product packaging boxes will choose sponge /eva as the main material, supplemented by color Ding cloth, paper and foam. The advantage of sponge is that it has low cost, which can save a lot of costs, and even if it is mounted and flocked, it is not too expensive, but the safety performance is clear to everyone, and it is extremely easy to be squeezed and deformed, So once there is too violent vibration, take the quality product of SLR camera as an example. If the extrusion sponge deforms and collides with the box body of the electronic product packaging box, it may cause some losses. Therefore, in common cases, in order to ensure the safety performance, the electronic product packaging box needs more protection inside the box than the general carton of the carton packaging factory.

Therefore, EVA has become the top priority of the packaging box of electronic products. The compression resistance of EVA is indisputable above the sponge. The emergence of EVA has changed many products in the electronic product industry, especially after the collapse of a mobile phone brand, the biggest obstacle for EVA to enter the packaging box Market of electronic products is that it is incompatible with the pit box, but at present, It can be said that the use of pit boxes and the need for inner support as electronic packaging box has disappeared. Now this epoch-making inner support product is being widely used. In fact, in addition to the customization of electronic product packaging boxes, products that need protection, such as beauty products and health products, now also use EVA materials with higher protection performance, so EVA can be said to be an epoch-making product of electronic product packaging boxes.