The demand for the grammage (measured in gsm, grams per square meter) of paperboard materials used in common paper packaging varies significantly across different industries. Grammage directly affects the thickness, strength, and applicable scenarios of the paperboard. Industries select different grammage ranges based on product characteristics, protection requirements, cost control, and environmental considerations. For instance, Jewelry Packaging Boxes differ markedly from many other special paper boxes in their specifications. Below is a detailed analysis:

-300x300.jpg)

Characteristics of Common Paper Packaging for Electronics: High-value products require shock resistance, compression resistance, and protection against transportation damage.

Typical Grammage:

1.Outer boxes typically use 300-500gsm grey-backed whiteboard paper or kraft paper, paired with corrugated board liners (e.g., B-flute/E-flute).

2.Precision instruments may adopt multi-layer structures with higher grammage facing paper (e.g., above 400gsm) and additional cushioning materials.

18-300x300.jpg)

The demand characteristics for common paper packaging in cosmetics and luxury goods: Emphasize high-end texture, exquisite printing, and tactile feel.

Typical basis weight:

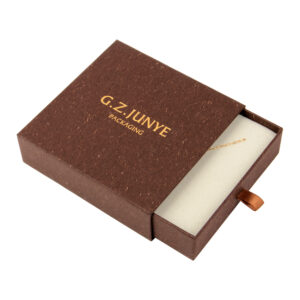

1. High-end gift boxes often choose special paper with a basis weight of 300-600gsm (such as tactile paper, pearlescent paper), and even use composite processes (hot stamping, UV, etc.).

2. Liners or drawer boxes may use lightweight paperboard with a basis weight of 250-350gsm, balancing strength and lightness.

14-300x300.jpg)

The demand characteristics of common paper packaging in the pharmaceutical industry are as follows: it needs to comply with hygiene standards, and some drugs require light protection and moisture resistance.

Typical basis weights are:

1. Medicine boxes often use white cardboard with a basis weight of 250-350gsm (easy to print instructions), and some use aluminum-plastic composite film.

2. The outer packaging of medical devices may use high basis weight cardboard (400gsm+) to ensure impact resistance.

10-300x300.jpg)

The demand characteristics for common paper packaging in gifts and holiday supplies are: emphasis on shape design and decorativeness, requiring a higher stiffness.

Typical basis weights are:

1. Gift boxes often use paperboard with a basis weight of 350-600gsm, which is convenient for scoring, die-cutting, and three-dimensional shaping.

2. Holiday decorations may use special art paper (300-400gsm) to enhance visual effects.