By employing the following 9 methods, the issue of looseness in the aroma diffuser packaging of medium-sized can be effectively addressed, ensuring the safety and stability of the products during transportation and storage.

7-300x300.jpg)

1. Precise Measurement: When Custom Aromatherapy Diffuser boxes, ensure accurate measurements of the dimensions of the aroma diffuser, including height, width, and depth, to design an appropriate packaging box size.

2. Cushioning Materials: Place appropriate cushioning materials, such as foam, bubble wrap, or pearl cotton, around the aroma diffuser to fill the space inside the electronics packaging box and reduce the movement of the aroma diffuser during transportation.

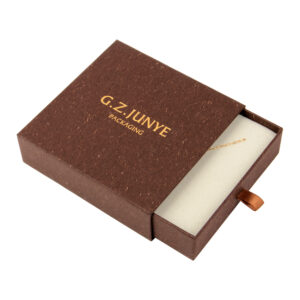

3. Custom-Fitted Lining: Design a custom lining that fits the shape and size of the aroma diffuser to ensure it is stable inside the packaging box and does not wobble.

2-300x300.jpg)

4. Lid Design: Ensure a tight fit between the lid and the box body, which can be enhanced by adding magnets, clasps, or tape to improve the sealing of the lid.

5. Material Selection: Choose cardboard materials with high strength and toughness to improve the overall structural stability of the packaging box.

6. Folding Design: Incorporate special folding structures in the packaging box design so that the box can closely conform to the shape of the aroma diffuser after folding, reducing gaps.

16-300x300.jpg)

7. Testing: After the packaging design is completed, conduct actual packing tests to check whether the tightness of the packaging box is appropriate and make adjustments based on the test results.

8. Packaging Instructions: Provide detailed packaging instructions to ensure that the aroma diffuser packaging materials and methods are used correctly during the packaging process to achieve the best packaging effect.

9. Quality Control: Conduct strict quality control during the production process to ensure that the size and quality of each packaging box meet the standards.